About the Department

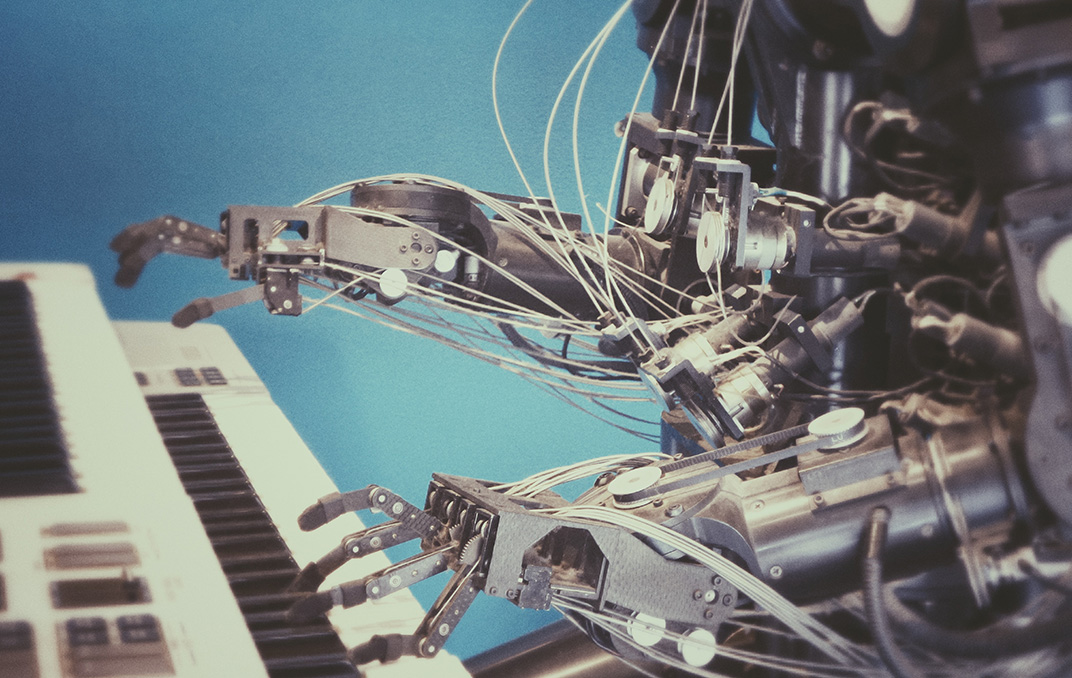

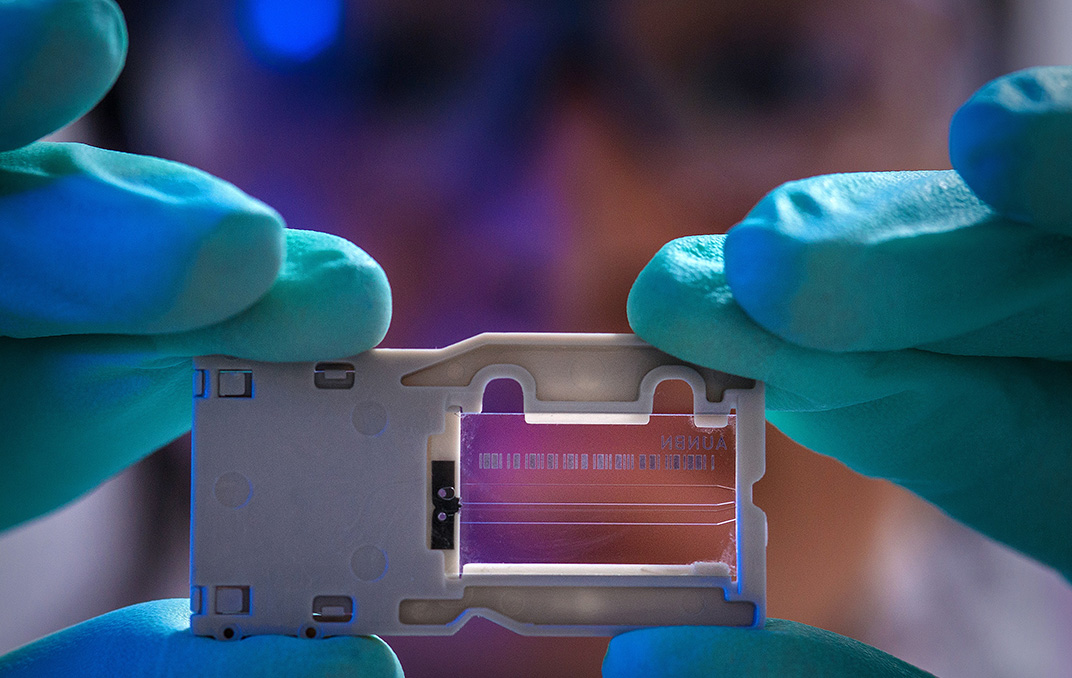

The Department of Mechanical Engineering, started right at the inception of BITS Pilani, Hyderabad Campus in August 2008. The Department has been ranked 351-400 as per the 2021 QS World Rankings in the field of Mechanical Engineering. It is one of the largest departments in terms of faculty strength, consisting of five (5) Professors, seven (7) Associate Professors, eighteen (18) Assistant professors and one (1) adjunct. The department offers a three tier structure of education i.e., B.E (Hons), M.E and PhD programmes with nearly 800 undergraduates, 100 post graduates and 80 Ph.D. students on roll. The department has dynamic and dedicated faculty, ably supported by competent technical and administrative staff. The laboratories are well equipped with some of the state-of-the-art scientific instruments and systems to undertake high-end teaching, research and developmental activities. The department has evolved over time to keep up with the ever-increasing challenges in technology development, while maintaining a strong base in the fundamental aspects of Mechanical Engineering. The basic objective is to generate high quality graduates through meticulous coursework and futuristic research activities. The students in the department are exposed to the problems faced by today’s societies, and are trained to address those problems through innovative thinking to develop appropriate technological solutions. In addition to the regular academic work, the students of the department are encouraged to participate in co-curricular activities and workshops.

Message from HoD

Our aim is to provide an environment in which all who work here can thrive, achieve their potential and do the very best. Currently, there are a total of 30 faculty members in the department working in the diversified field of mechanical engineering. The research work of the faculty members has been categorised into three broad streams: Thermal and Fluids Engineering, Materials and Design Engineering, and Manufacturing Engineering. Our department has a distinguished record in both teaching and research. Faculty members have excellent academic credentials and are highly regarded. They have been publishing their research works in highly reputed journals. Several faculty members serve on the editorial boards of national and international journals, review technical articles for journals on a regular basis, and organise international symposia and conferences. The total number of research projects undertaken by the faculty members during the last five years is 40 worth more than 9 crores. We have state of the art research facilities to support our academic programs and research. The funding obtained through research projects helps us to maintain and modernise our research infrastructure further.

An Institute of Eminence

An Institute of Eminence