Biosurfactants for various applications

Our primary focus is on microbial- derived surfactants, essentially from Bacillus sp. These biosurfactants with their superior functional properties are now being increasingly researched for applications in agricultural, cosmetic, food, healthcare and oil recovery sectors. The research works thus far (Phd and post doc), have focused on the development of an intensified bioprocess for the concomitant production and purification of these surface active biomolecules in stirred tank fermentors and to a lesser extent on the application side. As a part of my Ph d work, I developed a simple method for the synthesis of highly stable Ag-nanoparticles colloidal suspension, capped with lipopeptides, which showed very good antimicrobial properties. Currently, I am working on other facades of these biosurfactants applications, such as in cosmetic formulations, antimicrobial and oil recovery.

Hydrolytic enzymes for the production of reducing sugars

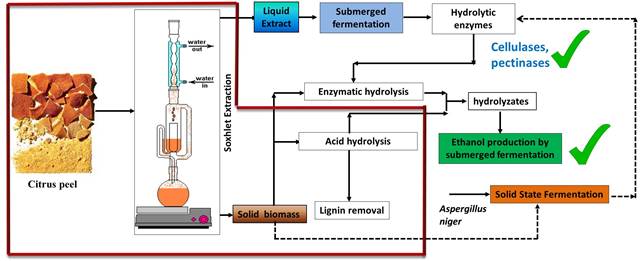

In years to come, the usage of ethanol-blended gasoline will become mandatory in all countries, as a measure to reduce the greenhouse gas emissions. So far, starch based feed stocks such as corn, sugarcane, potato and cassava have been used most widely for bioethanol production, but the motive of their use has led to the ever continuing debate of food vs fuel. Bioethanol production from lignocellulosic biomass has undoubtedly become a viable alternative, thanks to the improved biomass hydrolysis procedures through thermo-chemical methods. But, the focus in recent years has gradually been shifting towards the use of much cleaner and less-energy intensive process, such as, enzymatic processes for the hydrolysis of complex cellulosic substrates. To a greater extent, the research focus has been on lignocellulosic biomass from wood, grass and agricultural residues. Our current research endeavors are towards the use of fruit wastes from fruit processing industries as feed stock for the production of bioethanol. Also, we have been working on the production of biopolymers from the soluble sugars extracted from fruit wastes.

Cashew research (PI Prof Manjare)

Fermentation of cashew apple juice is still practiced as an art and hence systematic scientific understanding about Feni production process as a whole in terms of process consistency, olfactory property and chemical quality parameters of the distillate will help improve commercial value of Feni product. It has been observed that some of Feni makers have shown interests in upgrading their production value, due to recent trend in increased foreign export. Thus, considering the growing need for upgradation of the existing feni making units possessed by cluster of small scale cashew producers and also owing to scarce reports on Feni production process in general, we aim to investigate the influence of these listed out factors on the overall quality of feni.

Biopolymers for various applications

We mainly focus on thermophilic bacteria for the production of thermo-tolerant biopolymers which have imminent potential for applications in food, cosmetics, fly-ash disposal, enhanced oil recovery etc. We exploring the feasibility of using various agro-industrial wastes as substrates for the production of bio-polymer through solar powered bioreactors.

Positions available for PhD/N-PDF:

Interested students with Master's in Chemical Engineering/Biotechnology/ Biochemical Engineering and with a valid GATE score can contact me. Email: vivekr@goa.bits-pilani.ac.in

Self-funded students can also apply

*There will be a call for PhD under Institute research fellowship (BITS Pilani) in the month of Nov/Dec 2019. As per this scheme, the selected student will receive a monthly stipend from the Institute for a period of 5 years. (Rs. 31000 for the first 2 years, which would be enhanced to Rs. 33000 upon satisfactory performance)