Following testing facilities are available for Rotational Moulding:

Density of the Raw Material (Granules)

- Standard: ASTM D1505/D-4883/D-792 or ISO 1183, Method D

- Description: This test method involves the determination of the density of solid plastics. This test method is based on observing the level to which a test specimen sinks in a liquid column exhibiting a density gradient, in comparison with standards of known density

Powder Dry Flow Time and Bulk Density

- Standard: ASTM D1895-96 and ISO R 60 Adapted and redefined for use in Rotational Molding

- Description: To know how well the powder tumbles within the rotating mould Dry flow time needs to be tested. Bulk density of the powder gives an idea about the particle size and dispersion which can affect the material flow consistency and also indicate the packing quantity. For this purpose a funnel and cylinder are used and the test is conducted along with the dry flow time. The ARMA dry flow test kit is available for this purpose.

Melt Flow Index (MFI) and Melt Flow Rare (MFR) Testing

- Standard: ASTM D 1238 Method A , B, A/B

- Description: The data produced by this test method serves to indicate the uniformity of the flow rate of the polymer as made by an individual process. This test method covers the determination of the rate of extrusion of molten thermoplastic resins using an extrusion plastometer. After a specified preheating time, resin is extruded through a die with a specified length and orifice diameter under prescribed conditions of temperature, load, and piston position in the barrel.

Oxidative Induction Time (OIT)

- Standard: ASTM D 3895 using Differential Thermal Analysis (DTA)

- Description: Oxidative Induction Time (OIT) is a qualitative assessment of the level (or degree) of stabilization of the material tested. This test can be used as a quality control measure to monitor the stabilization level in formulated resin as received from a supplier. For example, OIT results are often used to select optimum resin formulations. Volatile antioxidants may generate poor OIT results even though they may perform adequately at the intended use temperature of the finished product.

Tensile Strength and Young's Modulus (For Resin/Product)

- Standard: ASTM D 638 /IS 13360

- Description: This test method is designed to produce tensile property data for the control and specification of plastic materials. Tensile properties provide useful data for plastics engineering design purposes. This test method covers the determination of the tensile properties of unreinforced and reinforced plastics in the form of standard dumbbell-shaped test specimens when tested under defined conditions of pretreatment, temperature, humidity, and testing machine speed. This test method is applicable for testing materials of any thickness up to 14 mm.

Flexural Modulus

- Standard: ASTM D 790

- Description: These test methods are used to determine the flexural modulus of unreinforced and reinforced plastics. Test specimens of rectangular cross section are injection molded or, cut from molded or extruded sheets or plates, or cut from molded or extruded shapes. Specimens must be solid and uniformly rectangular. The specimen rests on two supports and is loaded by means of a loading nose midway between the supports. The deflection is measured in one of using crosshead position. The values like Flexural strength and Flexural modulus are calculated that give vital information about the stiffness of the material.

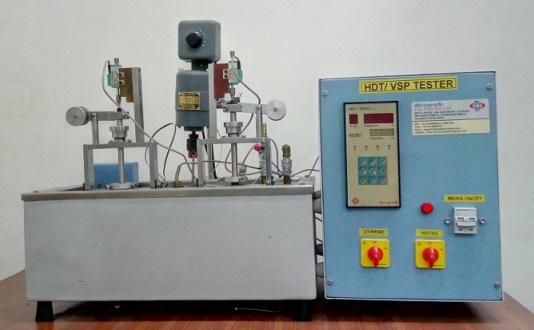

Heat Deflection Temperature (HDT)

- Standard: ASTM D 648

- Description: This test method covers the determination of the temperature at which an arbitrary deformation occurs when specimens are subjected to set of testing conditions with flexural load. This test method applies to molded and sheet materials available in thicknesses of 3 mm or greater and which are rigid or semirigid at normal temperature.

VICAT Softening Temperature (VSP)

- Standard: ASTM D 1525

- Description: This test method covers determination of the temperature at which a specified needle penetration occurs when specimens are subjected to specified controlled test conditions. This test method is not recommended for ethyl cellulose, nonrigid poly (vinyl chloride), poly(vinylidene chloride), or other materials having a wide Vicat softening range. This test method is useful in the areas of quality control, development, and characterization of plastic materials.

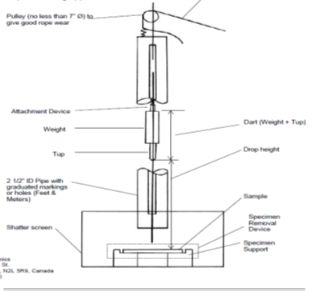

ARM Low temperature Impact Test

- Standard: Association of Rotational Moulders

- Description: This test includes determination of the energy required to cause the failure of plastic samples at low temperature by free-falling darts. Two types of failure are described in this test. Ductile failure - occurs when dart elongates the sample and punctures a hole in the test sample. Brittle failure - occurs when sample fails in a brittle manner, shattering or splitting into two or more pieces; or when the impacted areas break loose without elongation.